Types of filter press machines

There are three main types of this type of filter press:

Manual

Automatic

Hydraulic

Each of the production models can be used in a certain industry based on the needs. Obviously, the prices of this device will be different based on whether it is manual or automatic and the volume of operation. In the following, each of them has been examined and explained.

Manual press filter:

The cheapest type of these systems is the manual press filter. Plate movements, cake discharge and filtration in this model are done manually. As a result, it is mostly used for limited applications such as purification and processing in small volumes. The chassis of these devices is often made of iron, cast iron or steel.

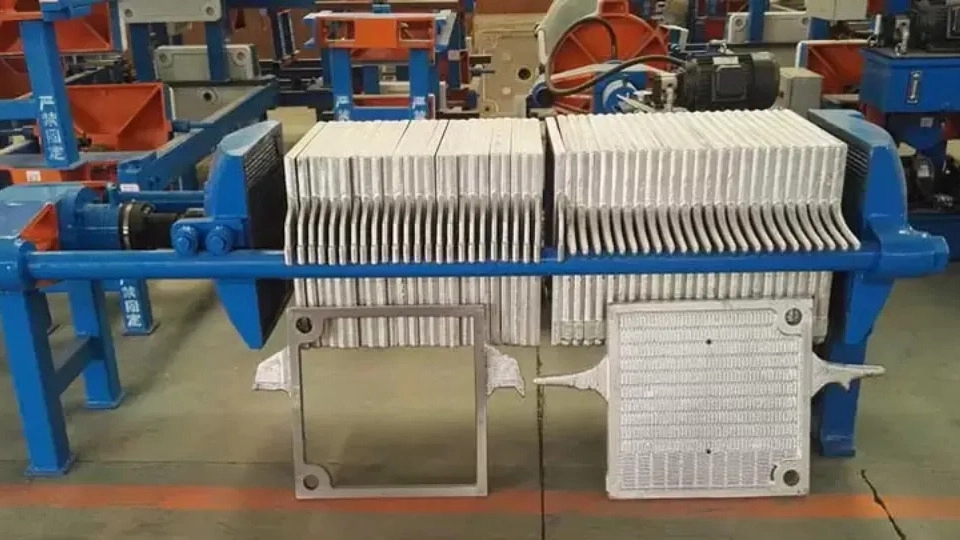

This model of filter presses is usually produced with 20x20, 40x40 and 60x60 plates with a limited number of plates (usually less than 15 plates). . In the process of making this manual filter press machine, the pump and hydraulic tank are not used, and the operator completes the sealing operation of the plates by means of the screw installed on the machine.

Hydraulic press filter:

Hydraulic press filter device is one of the most common pressure filters. Hydraulic filter presses are widely used in various industrial applications and are installed in the following conditions:

small systems with a small number of plates; that the employer wants to perform the sealing operation of the solution in the device without manpower and with hydraulic pump pressure.

In large devices or with a large number of plates; which is practically impossible or very difficult to seal the solution in the device by human power.

Due to the uniform pressure that is created between the plates in the hydraulic press filter compared to manual pressure filters, the moisture content of the discharged cake will be very low. So that the output cakes of this type of filters have only between 18-25.5% moisture. Also, the purification capacity increases. Cake unloading in these devices is done both manually by the operator and automatically by the device.

Automatic filter press:

Automatic filter press devices are produced in the following two types:

Chamber

Members

Their difference is in the types of plates, operation The compression of the suspensions and the placement of the plates. Fully automatic filter presses are very different from normal press filters. The separation/dewatering operation in these devices is performed without the presence of the user and operator with the highest speed and quality. As in these systems, the following operations are performed completely automatically and without the operator's intervention.

Opening and closing the jack,

moving the filter press plates,

loading and unloading the cake,

washing Pages

Preparing the device for the next cycle

Automatic filter press devices can include a vibration system. In this way, after the completion of the dewatering and cake forming operations and the opening of the machine plates, the vibration of the machine starts so that the cakes formed between the plates are completely separated and the discharge is done with high precision. The advantages of the automatic filter press include the following:

A high level of automation and efficient operation is provided at the same time.

Maximum adaptability through development modules and other automation options

Simple and economical filtration due The highest degree of dewatering and shortening of the cycle time

lower costs of employing personnel; Due to the fully automatic implementation

high security through the use of the latest security technology

performing filtration accurately in a large volume and small space

high filtration speed

complying with industrial and public standards.

Production of cakes with lower moisture percentage (preventing wastage of materials).